THE PROJECT

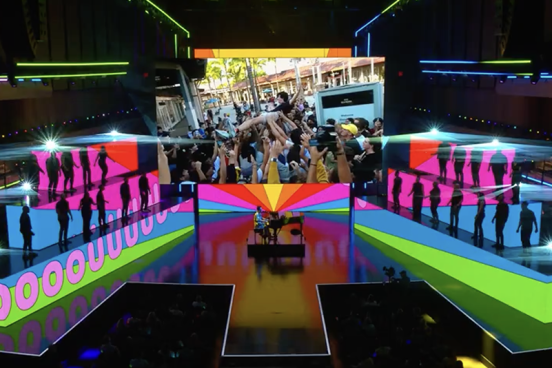

Shortcut LED Stage has been built by Creative Technology in the heart of Nordisk Film’s legendary HQ in Copenhagen. Film makers, production companies and other visual storytellers are now able to shoot and tell stories in a flexible, creative, cost-cutting and environmentally friendly way.

Creative Technology worked alongside the Nordisk Film-owned VFX and post-production company Nordisk Film Shortcut to create the Shortcut LED Stage – a full 360° LED stage, 16 metres in diameter, with walls and ceiling totally covered with LED panels. On Shortcut LED Stage it is possible to shoot actors, sets and props against vivid, photorealistic, virtual backdrops – everything from alien planets and fantasy worlds to underwater shoots, vast deserts, and vibrant cities from across the world – and you can shoot scenes taking place in many different locations and countries in one day.

THE DETAILS

In January 2022, Creative Technology was asked to build a 360-degree LED stage in Copenhagen, for Nordisk Film and their post-production company Shortcut. They had visited the ARRI X CT stage in London decided that they wanted to create a similar one to enable film production in a virtual environment. In collaboration with the agency Kreaktivitet AS, Creative Technology started planning the construction in March 2022.

The work began with preparing the building and the floor for the installation, which in its entirety weighed a whopping 33 tonnes. A steel structure was first set up as a framework in which the rest of the construction could be assembled. Cabling was pulled out and rack rooms were built. At the end of July the first delivery of LED panels arrived, and the team of 14 people could start building the LED volume itself.

– We started with the round section, after which we built the roof, which we raised before we continued with the round section. Last we put up the doors, says Lennart Franksson, senior project manager at Creative Technology.

They had originally intended to start with the LED ceiling, but since the transport of these panels had gotten stuck outside Hamburg, they had to rethink and started with the round part instead.

– Our ship was stuck outside Hamburg for a month, loaded with the majority of the LED panels. The port of Hamburg was closed due to a strike, as the dock workers did not want to move Russian containers and our goods remained at sea. We negotiated with the supplier and asked to change the Port of Call, i.e. the port where the goods were to be unloaded. This process took several weeks.

The negotiations became a real thrill. Just an hour before the ship was due to turn around and head back to Asia, the decision was made that the cargo could go to Rotterdam. There it was unloaded and driven by truck bound for Copenhagen.

As the entire work schedule was delayed by a month and a half due to the delivery issues, the building work became very compressed and 2/3 of the total assembly was done in a single week.

– Fortunately, we received an extra working force of three fantastic people from Creative Technology Australia. It was winter there at the time and they had a quieter period, so they called and asked how they could help. We were also joined by a talented guy from South Africa, says Franksson.

The LED volume began to take shape and finally a completely enveloping 360-degree LED stage was in place, something that is still relatively unusual as many LED stages are built with an opening and cannot be closed completely.

The LED construction consists mainly of ROE Black Pearl BPv2, but ROE Carbon Black and Roe Black Marble 4 Matte panels were also used, the latter for the floor. These screens work very well in camera production as they have a refresh rate that minimizes the risk of moiré and other disturbances in the camera image.

– ROE also has developed Ghostframe (frame re-mapping), which is a very useful technology in virtual production, says Ole Bergström, project manager at Creative Technology.

CT was also responsible for the installation of the disguise media servers, whose task is to play the graphics on the LED screens. A total of nine units were installed, where five RX2s or “workhorses” render the graphics and send them to four VX2s, so-called “actors”, which in turn send the content to the LED processors.

– The RX2s render the graphics that Nordisk Film Shortcut creates in the game graphics engine Unreal Engine so that it can be used in a 3D space. These machines are enormously powerful and an incredible processing power is required for this type of work, says Bergström.

In addition to possessing advanced technical knowledge, the technicians and project managers involved were faced with extremely high demands on accuracy, endurance, and the ability to cooperate with several different actors in the project. Having a strong desire to learn new things also proved to be an advantage.

– We have learned so much on this project. I sat for a whole week to just learn the new elements that were constantly required for the project. The opportunity to do a job like this means that I am now a full-time project manager at CT’s department for fixed installations – Systems Integration. The chance to once again participate in this type of project is an enormous motivation, says Bergström.

In mid-August, the installation work was completed and tested before the studio was handed over to Nordisk Film Shortcut. More than eight months of planning and building work resulted in Northern Europe’s first full-scale LED stage where filmmakers can now shoot films and commercials without having to travel to various locations or wait for the right light or weather for their scenes.

– This is the largest installation project we have ever undertaken and it has been awesome. I am very proud of what we have done, says Franksson.

EQUIPMENT USED

LED:

Roe Black Pearl 2 V2, Primary LED-screen, 56 x 12 panels built in a semicircle, 6 metres high

Roe Carbon Black 5, Secondary LED-screen and LED-Ceiling, 616 panels completes the circle, complete with sliding LED-barndoors and a fully covering LED-ceiling.

Roe Black Marble 4 Matte, LED-Floor tiles (Rental from CT).

MegapixelVR Helios, 6 LED controllers plus an MVR Omnis for remote management.

Playout:

Disguise: Five VX2 and four RX2

Camera Tracking:

Stype Follower, Camera Tracking kit

Power Distribution:

3 x Stagesmart C72tv SmartPDUs with network reporting

Rigging:

Steel Structure supporting the LED, ceiling and curved walls delivered by 23

Facts about Shortcut LED Stage

- Full 360° LED stage

- 16 metres in diameter and six metres high

- Walls and ceiling covered with LED panels

- Full or partial LED floor can be laid

- The screens emit up to 6,000 nits, providing a wide and detailed light spectrum

- Vehicles, boats and planes up to 15 metres can be placed inside the LED Stage